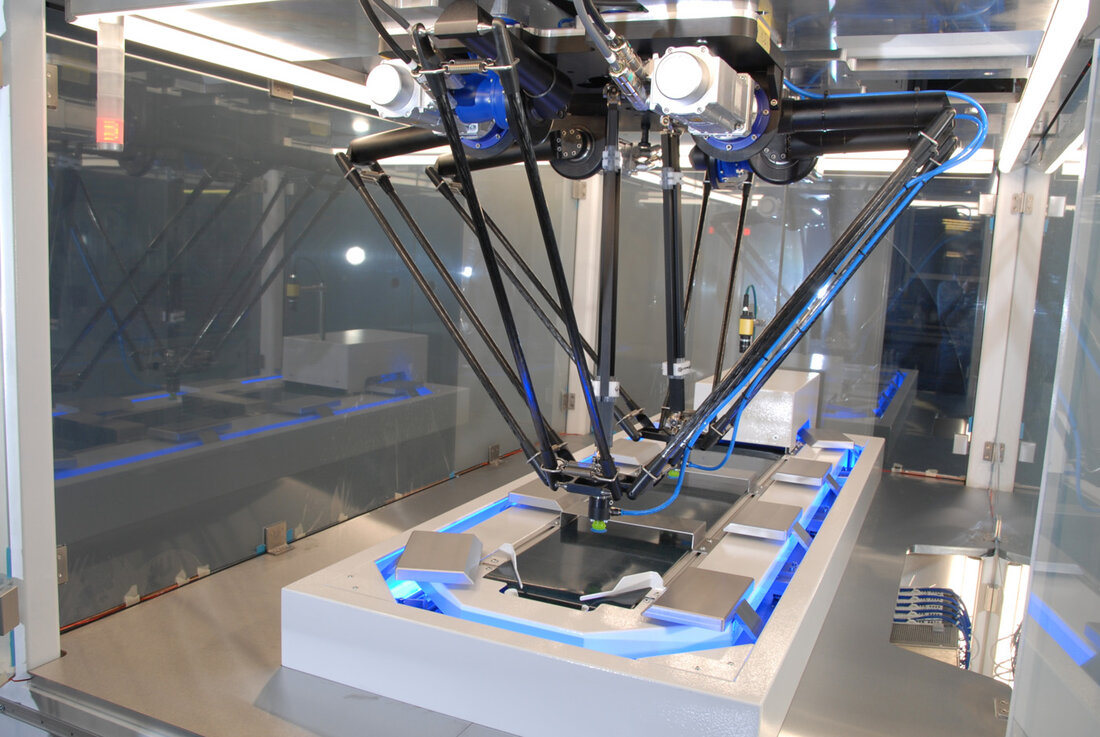

DELTA ROBOTER

40768

Pick & Place solutions with highest accuracy designed for small space demands, having a high number of picks specially adapted to your application.

Chocolate bars for show purposes are dynamically sorted at the exhibition, spat out by a vacuum belt and handed over to the customers with labels. The focus is of course on the individual products such as sensor technology, RFID and security systems, which can be presented with this application. The experience gained from such application-oriented exhibition machines is of course transferable to any requirements for industrial purposes in customized machinery engineering.

Contact us!

Description

- Feeding system via an automatic but also manually operated magazine

- Detection of the position, location and product via a high-resolution camera

- Picking up and turning the individual products by two Delta robots

- Overlapping work areas of the robots with feedback- and monitoring function

- Special suction or gripper systems adapted to the respective products

- Sorting and buffering of the different products

- Fine tuned vacuum pumps

- Predetermined depositing of the products on a conveyor belt for labelling and discharge

- Detection of rejects

- Highest precision in the Pick & Place process

- Modern controller and drive technology

Technical Data

| Mech. machine speed | Up to 200 P/min |

| Working area | ø800 mm x 250 mm |

| Unit load | Up to 3 kg |

| Accuracy | 0,1 mm |

| Rotation degree | Up to 180 |

| Fields of application | Food, packaging, pharmaceuticals, cosmetics, electronics etc. |