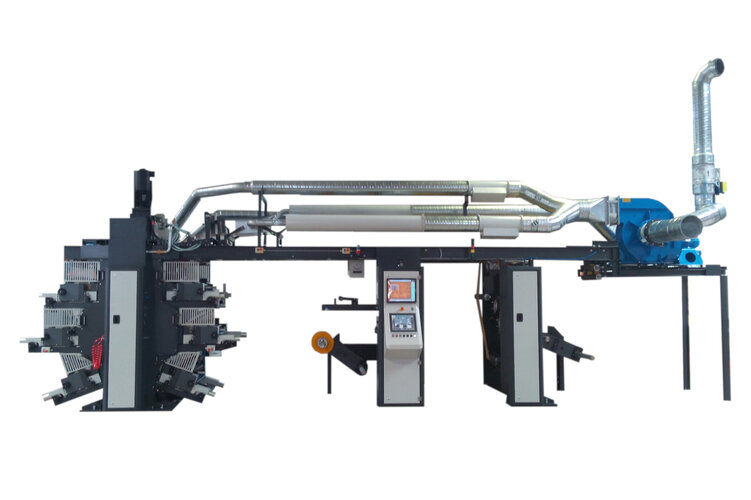

FLEXO PRINTING MACHINE FD2

19858

Our reliable Flexographic Printing Press FD2 is mainly taken by our customers for polyamide sausage casing printing use. This printing press is capable for 360° front- and backside printing in one production step. Nowadays the “printing over the edge” technology is state of the art – a squeegee will scrape the ink from central impression cylinder. Modern control technique and intuitive handling with touch panel functionality makes it easy to use.

Description

Type: FD2 (Central impression, Gear driven)

- 4, 6 or 8-Color Printing Rack with strong dimensioned Impression Cylinder, also available with temperature control for UV-Colors

- 4, 6 or 8 complete Flexo rotary printing mechanisms for Solvents or UV-Colors

- Double bearing supported Roller and Cylinder

- Half-automated Unwinding and Rewinding Device, with double Rotating Arm

- Easy sleeve replacement of the printing cylinder without disassembling

- Available Drying Systems: Warm Air, UV

- Turning Device for front- and backside printing in one production step

- Adjustable Web Tension due to an electrical connected Servo-Drive Motor

optional:

- Corona device, Powder device, Video web-tracking

Technical Data

| Working width | Max. 500 mm |

| Material width | Max. 530 mm |

| Format length | 290 bis 650 mm |

| Format steps | 5 mm |

| Mechanical machine speed | 5–150 m/min |

| Dimensions | 11,4 x 3,5 x 4,2 m |

| Weight | Ca. 15.000 kg (Typ FD 2/1910) |