ROTARY DIE CUTTER

65445

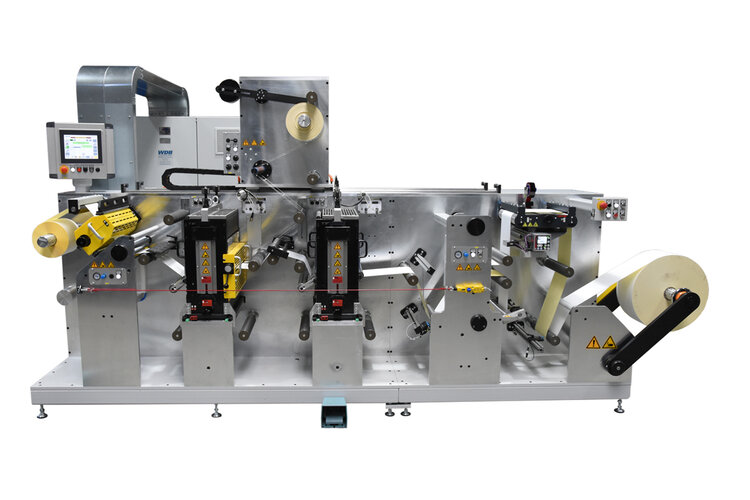

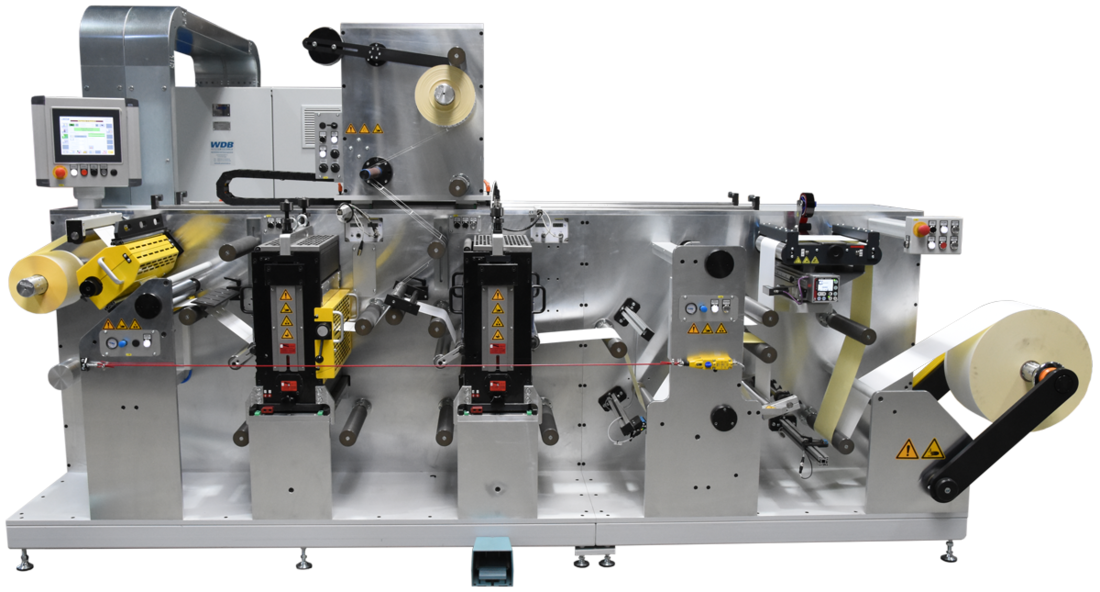

Our rotary die-cutter RSM-330 is characterized by a precise and solid steel construction to withstand the extremely dynamic cutting forces. Slitting device, flag detection, digital pressure measuring devices, servo driven pulls and winders, longitudinal cutting device and a touch panel with simple operating concept are included.

If you have special demands or requirements for your machine, please contact us, we will be pleased to build your individual customized machine!

Description

Type: Double Rotary Die Cutter RSM-330 / 2

- Precise and solid designed steel construction, to withstand the extreme, dynamic cutting forces

- Cross beam made out of steel to apply the cutting force onto the distance rings

- Double bearing supported unwinder with pneumatic expansion shaft

- Side edge control with integrated cutting table

- Dancer device, incl. linear potentiometer

- Splice detection sensor

- Slitter with four circular score cutters

- Machine pull, incl. rubberized pneumatically adjustable nip, servo driven

- Punching station is a highly precise and solidly designed steel construction. The partially overdimensioned components ensure the necessary rigidity to withstand the extremely dynamic punching forces

- 2x rotary die cutter

- Cross beam made of steel with 2 fine-thread spindles to transfer the punching pressure to the bearer rings

- Including safety covers

- Manual side register adjustment +/- 5 mm

- Incl. impression cylinder

- Incl. base plate for punching station

- Insetter control, one sensor before the first punching unit

- Pressure gauges per punching station for digital display of the right and left punching pressure in kN

- Grid take-off supported on one side

- Single side bearing supported matrix waste winder

- Rollers with a diameter of max. 400 mm and a width of 350 mm, max. roller weight 40 kg.

- Roller support with pneumatic tension shaft for a core diameter of 76 mm.

- Feeding roll, which can be put on the grid by a swing arm, driven by servo motor

- Dancer device, incl. linear potentiometer

- Pull, incl. longitudinal slitting device 3 upper and lower knives, driven by servo motor

- Control system, operating panel and electrical equipment

Technical Data

| Working width | Max. 330 mm |

| Material width | Max. 350 mm |

| Material thickness | 40 – 250 µm |

| Format width | 200 bis 635 mm |

| Roll diameter | Unwinder: max 1000 mm / Rewinder: max 400 mm |

| Roll weight | Max. 150 kg |

| Web tension | 20-100 N |

| Mech. machine speed | 5–100 m/min |